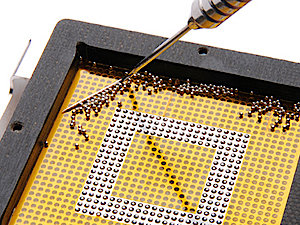

Manual camera-supported adjustment and placement of components via the MCP positioning arm. Precisely aligned to the pad structures of the PCB, it is accomplished in a user-friendly and reliable way.

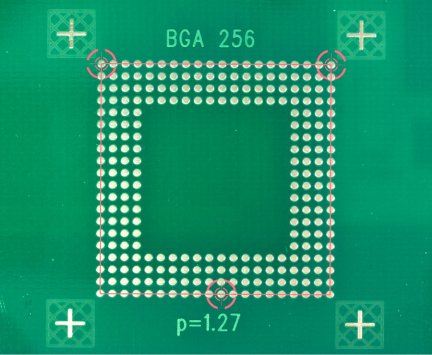

The camera determines the destination of the component. Three markers are set within the EASYSOLDER 07 software to define the position of the component on the board.

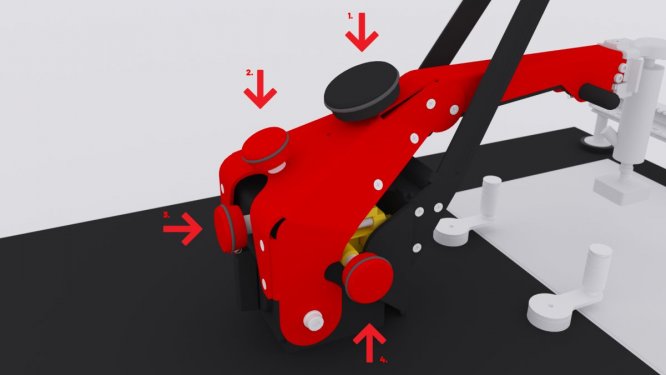

With the MCP arm's shifting mechanism, the component is roughly placed over the target position. The component can be perfectly aligned by fine adjustment in the X,Y,Z,Θ axes using the control knobs. The chip is picked up by a vacuum tool then carefully placed on the PCB.

The high-resolution camera enables the repeat accuracy of the placement. Depending on the application, the lens can be set to different zoom levels.

The MCP technology thus ensures reliable placement of almost all conventional components in manual rework processes.