The MINIOVEN is a compact and cost-effective reballing device that is particularly suitable for research and development and small series production.

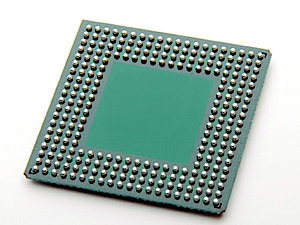

Desoldering and cleaning of residual solder from the component, reballing of the chip and finally solder back to PCB may repair the assembly without need of any new component. Thus, the application of new solder spheres with either the same or different alloy can restore functional components to full usability.

Reasons for reballing:

- Development and prototyping

- Switching from lead-free to leaded solder balls or vice versa

- Excessive component costs

- Limited component availability

- Faulty assembly or the need to fill in missing balls

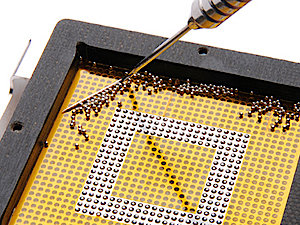

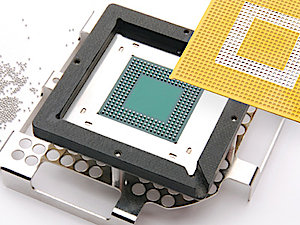

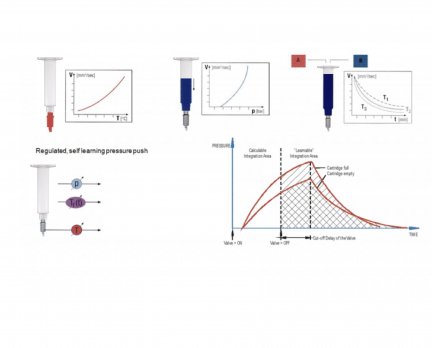

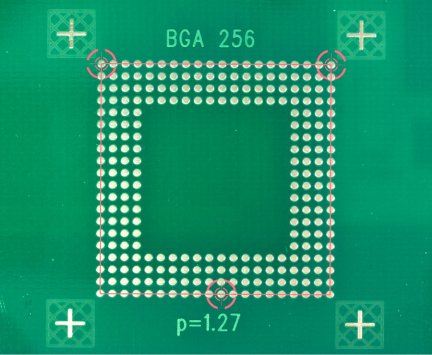

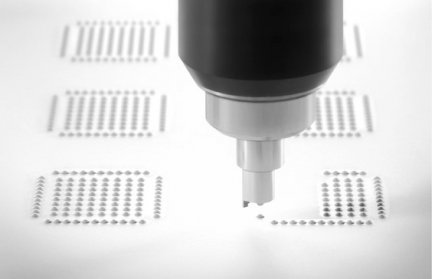

For this purpose, the components are first placed in a special reballing holder. A mask with holes corresponding to the pattern of the contact pads on the component is placed onto the component in the holder. Solder balls are distributed on the mask until all holes are filled with a solder ball.Finally, the controlled and gentle reflow process in the MINIOVEN 05 completes the procedure.

Martin offers standard and customized masks and frames. For special tasks, universal masks can easily be adapted with kapton tape to reball chips with unusual pad structures. The standard holders and masks are designed for components with a size of 1 mm x 1 mm to 60 mm x 60 mm.

For detailed information, you can either watch the application video or contact your local representative.