1 | 5

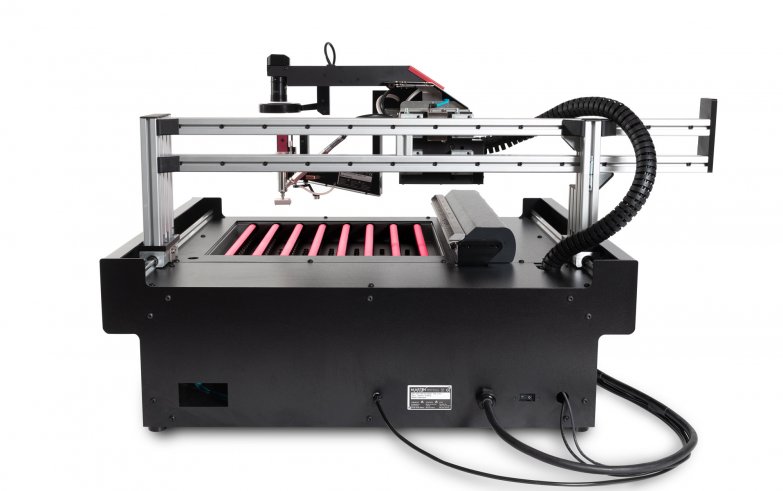

EXPERT 10.6 RS

5,300 W Rework station

Semi-automatic rework station with gantry system for small to very large components

Semi-automatic rework station with gantry system for small to very large components

Top FeaturesCamera-supported rework

Flexibility

Good accessibility of all components on the board via the gantry system & compact footprint at the same time

Under-heating system

Large PCBs 500 x 500 mm²

Performance

High cycle time due to easy prepositioning of the arm via gantry system

Multifunctionality

One device for all processes, including desoldering, pad cleaning, automatic positioning and soldering

Process control

Automatic profiler for under- and top-heating systems; Repeatable placement

Software

Simple, intuitive, tablet-compatible

EXPERT 10.6 RS

Semi-automated rework station with Gantry system for small to very large and massive components. The proven hybrid underheater allows gentle heating of boards with dimensions up to 500 x 500 mm². For safe handling of all components, the precise positioning system can navigate to any point on the PCB. Pre-positioning is performed via the smooth-running XY gantry, while fine positioning and placement is fully automatic using reliable Martin precision/technology.

Product variations in the shop

| DB00.1073 | EXPERT 10.6 RS Hybrid rework system with gantry 5300W Article Nr.: DB00.1073 |

Standard equipment

- Set of placement nozzles XL-type (BGA/CSP) 5 mm, 8 mm, 15 mm with O-Ring

- Set of solder nozzles (BGA) 15 mm, 27 mm, 35 mm, 40 mm

- Two camera lenses (BGA, CSP)

- Two thermocouple sensors (type K)

- Four PCB magnet holder 40.5 mm (standard)

- Two PCB clips to install at hand rest

- Manual

- Intuitive software EASYSOLDER 07 with touch integration

Components

- BGA

- BGA up to 67x67mm

- µBGA/CSP

- QFN

- DFN

- QFP

- PGA

- RF shields

- RF frames

- Rework on flex

- Package on Package (PoP)

- Connectors & Sockets

- Underfilled or coated components

- LED rework

- Daughter boards

- Sub assemblies

Processes

- Desoldering

- Soldering

- Solder removal

- Dipping

- Paste printing

- Reballing

- Dispensing

- Multichip soldering

Technical details

| Power consumption: | 5,500 VA | ||||||||||||||||||||||||||

| Power solder pen: | 400 W, 35 l/min | ||||||||||||||||||||||||||

| Power under-heating system: | 1,200 - 5,000 W | 8 x IR-lamps | |||||||||||||||||||||||||

| Size under-heating system: | 450 x 420 mm² | ||||||||||||||||||||||||||

| Max. PCB size: | 500 x 500 mm² | ||||||||||||||||||||||||||

| Resolution motion system: | 0.001 mm | ||||||||||||||||||||||||||

| Placement accuracy: | ± 0.015 mm | (Flip Chip)* | |||||||||||||||||||||||||

| ± 0.030 mm | (CSP) | ||||||||||||||||||||||||||

| ± 0.040 mm | (BGA) | ||||||||||||||||||||||||||

| ± 0.070 mm | (Maxi BGA)* | ||||||||||||||||||||||||||

| ± 0.115 mm | (Maxi BGA XL)* | ||||||||||||||||||||||||||

| High resolution CMOS-camera: | 5 Mio. Pixel,USB2 | ||||||||||||||||||||||||||

| Size of component: |

| ||||||||||||||||||||||||||

| Mains: | 1Phase, 230VAC, Fuse 25A | Connector Type CEE 32A (3 phase) | |||||||||||||||||||||||||

| Pressurized air: | 5-8 bar, 100 l/min | clean, dry air | |||||||||||||||||||||||||

| Dimensions: | 1030 x 630 mm2 | ||||||||||||||||||||||||||

| Weight: | 85 kg | ||||||||||||||||||||||||||

| * Optional extras |

Downloads

| Product flyer | 1 MB | Download |