EXPERT 10.6 HXV

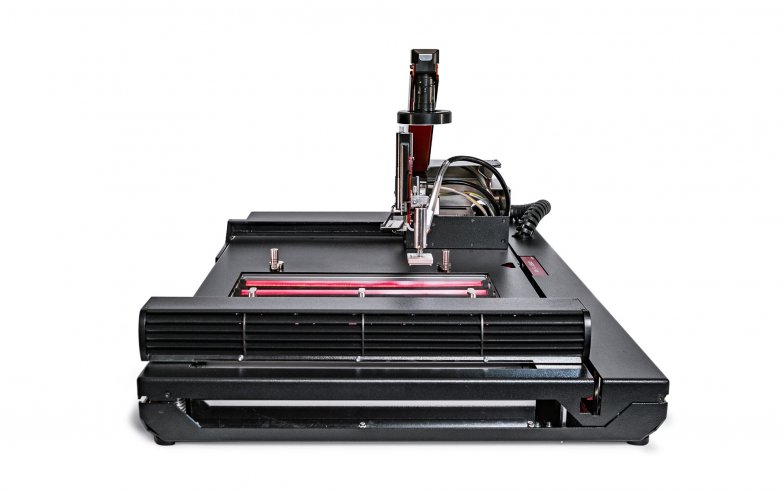

Semiautomatic hybrid Rework station for repairing large circuit boards, such as server- or mainboards.

Top FeaturesCamera-supported rework

EXPERT 10.6 HXV

Rework Station with 5,300 W hybrid under-heating system. The heating area of 450 x 420 mm2 is adjustable to PCB size. Automated SMD placement process by Auto Vision Placer (AVP) incl. EASYSOLDER 07 software package and DBL 06 control unit with six high resolution sensors inputs for thermocouples (Type K).

This system is particularly suitable for large size PCBs like PCs, Laptops and Server Boards with small up to very big components.

Product variations in the shop

| DB00.1066 | EXPERT 10.6 HXV Hybrid rework station 5300W, autom. placement Article Nr.: DB00.1066 |

Standard equipment

- Tool set for dispensing, placing, residual solder removal and soldering with magazine

- Set of placement nozzles XL-type (BGA/CSP) 5 mm, 8 mm, 15 mm with O-Ring

- Set of solder nozzles (BGA) 15 mm, 27 mm, 35 mm, 40 mm

- Two camera lenses (BGA und CSP)

- Two thermocouple sensors (type K)

- Four PCB magnet holder 40,5 mm (standard)

- Three PCB clips to install at hand rest

- Foot switch

- Manual

- Intuitive software EASYSOLDER 07 with touch integration

Components

- BGA

- BGA up to 67x67mm

- µBGA/CSP

- QFN

- DFN

- QFP

- PGA

- RF shields

- RF frames

- Rework on flex

- Small passives down to 0402

- SON

- Sockets

- LGA

- Package on Package (PoP)

- Connectors & Sockets

- CPU

- Underfilled or coated components

- Film capacitor

- LED rework

- Daughter boards

- Sub assemblies

- Interposer boards

Processes

- Desoldering

- Soldering

- Solder removal

- Dipping

- Paste printing

- Reballing

- Dispensing

- Multichip soldering

Videos

The semi-automatic Rework station with hot gas facilitates the reliable and precise rework of BGA, CSP, and QFN components, connectors, sockets, micro SMDs and more.

The EXPERT 10.6 HV and HXV are perfect solutions for desoldering multiple components in one step. With this opportunity a tremendous amount of time can be saved.

Preparing the PCB surface for the soldering process with accurate residual solder removal using the combination of a hot-gas source with a vacuum pen.

Technical details

| Power consumption: | 5,500 VA | |||||||||||||||||||||||||||||||

| Power solder pen: | 300 W, 35 l/min | |||||||||||||||||||||||||||||||

| Power under-heating system: | 1200 - 5000 W | 8 x IR-lamps | ||||||||||||||||||||||||||||||

| Size under-heating system: | 450 x 420 mm2 | |||||||||||||||||||||||||||||||

| Max. PCB size: | 480 x 480 mm2 | |||||||||||||||||||||||||||||||

| Resolution motion system: | 0,001 mm | |||||||||||||||||||||||||||||||

| Placement accuracy: | ± 0,015 mm | (Flip Chip)* | ||||||||||||||||||||||||||||||

| ± 0,030 mm | (CSP) | |||||||||||||||||||||||||||||||

| ± 0,040 mm | (BGA) | |||||||||||||||||||||||||||||||

| ± 0,070 mm | (Maxi BGA)* | |||||||||||||||||||||||||||||||

| ± 0,115mm | (Maxi BGA XL)* | |||||||||||||||||||||||||||||||

| High resolution CMOS-camera: | 5 Mio. Pixel USB2 | |||||||||||||||||||||||||||||||

| Size of components: |

| |||||||||||||||||||||||||||||||

| Mains: | 1Phase, 230VAC, fused 25A | Connector Type CEE 32A (3 phase) | ||||||||||||||||||||||||||||||

| Pressurized air: | 5-8 bar, 100 l/min | clean, dry air | ||||||||||||||||||||||||||||||

| Dimensions: | 1030 x 630 mm2 | |||||||||||||||||||||||||||||||

| Weight: | 96 kg | |||||||||||||||||||||||||||||||

| * Optional extras |

Downloads

| Product flyer | 0.9 MB | Download |

Optional extras

| SF66.0501 | Tool Slider 40mm for AVP 4.1XL Article Nr.: SF66.0501 | ||||||

| SF64.0525 | Dip Tool 0.08mm with squeegee for tool shuttle 32 / 40mm Article Nr.: SF64.0525 | ||||||

| SF64.0526 | Dip Tool 0.15mm with squeegee for tool shuttle 32 / 40mm Article Nr.: SF64.0526 | ||||||

| SF64.0527 | Dip Tool 0.22mm with squeegee for tool slider 32 / 40mm Article Nr.: SF64.0527 | ||||||

| SF66.0526 | Dip Tool 0.15mm with squeegee for tool shuttle 40mm Article Nr.: SF66.0526 |