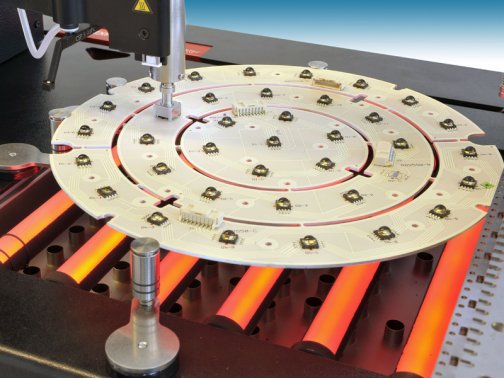

PC Boards, with high density of sensitive components, require gentle heating of the whole board and accurately controlled soldering profiles.

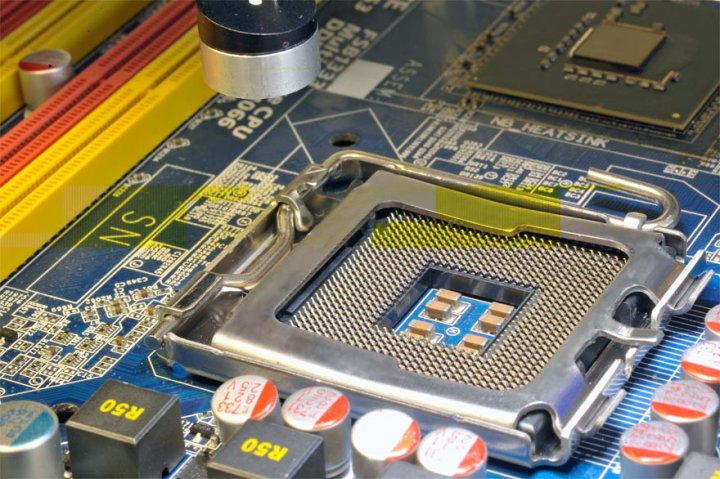

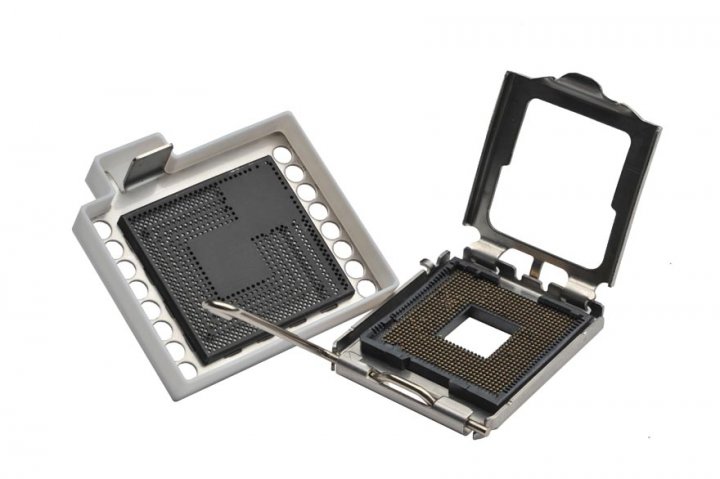

The new MARTIN Expert-10.6 generation is eminently suited to these tasks. Powerful, large area Hybrid Underheaters with up to 10,000 W of energy available and heated areas up to 500 x 650mm ensure that the required energy is distributed evenly. Socket specific tools enable simple and accurately repeatable handling of components. Neighbouring components, such as small passives, are neither desoldered nor overheated.

The software and camera controlled Positioning arm of the Expert-10.6, the Auto-Vision-Placer, lifts even heavy, metal framed sockets without problem and exactly replaces them on the board.

With intuitive software control of the proven placement technology and the available options, the Expert-10.6 family represents cost-effective equipment, spanning the complete rework process, especially for contract reworkers and repair centres.