This research illuminates a collaborative effort between Ruhr-Universität Bochum, Martin GmbH, and Leutz Lötsysteme GmbH, resulting in an innovative solution for the automatic and non-destructive removal of components embedded with underfill material. The technology is based on new tooling and intelligent guidance.

The collaborative initiative led by the Production Systems Chair at Ruhr-Universität Bochum, in conjunction with Martin GmbH and Leutz Lötsysteme GmbH, aims to advance the field of PCB repair. The development addresses challenges associated with manually and automatically removing components encapsulated with underfill material.

The use of underfill technology is crucial for the protection and reliability of chips on printed circuit boards and other substrates. The underfill material is poured over the chip and substrate to protect them from moisture, heat and mechanical influences. Until now, however, removing this material has been a major challenge. The repair of components was heavily dependent on the underfill materials used. Neither manual nor automatic removal methods have been satisfactory.

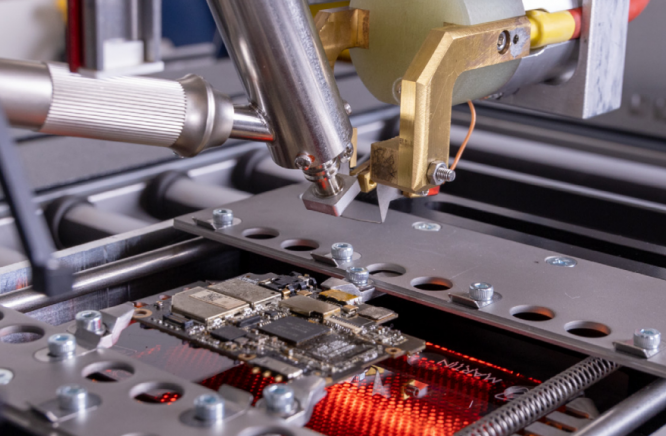

Leutz Lötsysteme GmbH's innovative cutting blade, supported by accompanying software and an advanced robotic arm, facilitates non-destructive underfill material removal. This collaboration opens new possibilities for PCB repair, reducing resource loss.

"Our aim was to develop a technology that is not only effective and cost-efficient, but also enables the non-destructive removal of underfill material. This opens up completely new possibilities for the repair of printed circuit boards and reduces the loss of valuable resources." Claus Leutz from Leutz Lötsysteme GmbH.