Continuously increasing quality demands require that companies carry out routine audits to record processes and the performance of equipment. Checking central functions such as hot air temperature, air flow and electronic measurement amplifiers, can now be established by the user. A considerable amount of time and money can thus be saved by documenting these parameters in house.

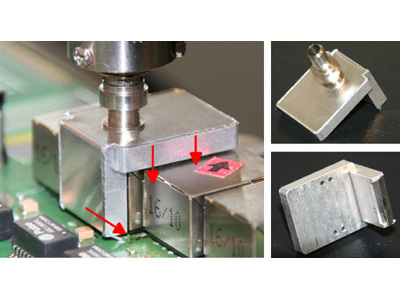

MARTIN introduced its Calibration set CHG 01 at the SMT 2012 show in Nuremberg. Safely and conveniently housed in a carrying case, the measurement heads (especially the temperature sensor with digital controller) allow temperatures up to 400°C to be measured with an accuracy of ±1%. Air flow, crucial for energy transfer, can also be established.

Rework system users value the certainty of knowing how effective the energy transfer is from the hot gas source to components, since this greatly influences the quality of rework profiles. Influenced by DIN ISO standards for audits, documentation suggestions and hints for the correct interpretation of measured values are provided.

Calibration Set for EXPERT Systems

Wessling, Mai 2012.

MARTIN GmbH has introduced a new Calibration Set to go with the EXPERT Series of rework stations. Five measurement and calibration adapters serve to establish and verify the most important performance criteria. Preparation for calibration audits couldn’t be easier.