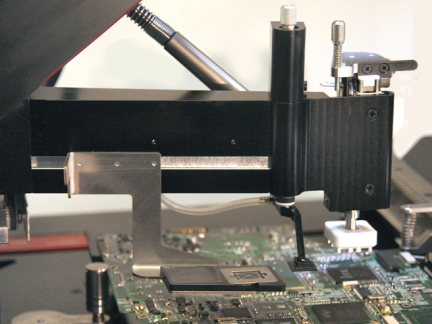

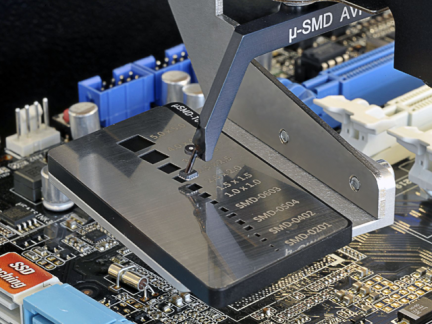

Reballing at the highest level

MARTIN GmbH hereby introduces the revised MINIOVEN 05 with improved hybrid heating technology. In the updated version of the device preheated air is fed into the processing chamber, thereby contributing to a faster and very homogenous heating of the electronic component. The advanced electronic heating allows accurate control of the temperatures in particular in the peak area. Also, the cooling process was improved as the internal case fan generates a higher airflow rate and thereby, cools down the component temperature much faster and at the same time reduces the total process time.

Furthermore, numerous minor technical innovations found their way into the device resulting in increased performance and operating comfort: an additional thermal sensor can be connected to the device, for example. It is used for monitoring the temperature of the component during the automatic profile creation and for optimum profile parameter configuration. The introduction of a new process technology and additional profile parameters (soak phase) lead to improved temperature stability in repeated heating processes.

The PC software EASBEAM V2 enables easy editing of all profile parameters. In conjunction with the HOTBEAM bottom heater, EASYBEAM V2 has already been successfully introduced. It offers, also for the MINIOVEN 05, the possibility of temperature profile indication and data record saving on a computer.

A large display and a completely redesigned menu navigation enable the user to use the device quickly and intuitively.