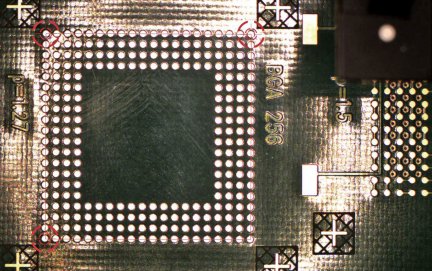

Software supported, application independent placement of components is achieved by Advanced Vision Placement.

TechnologiesTechnologies for precision

ReworkTechnologies

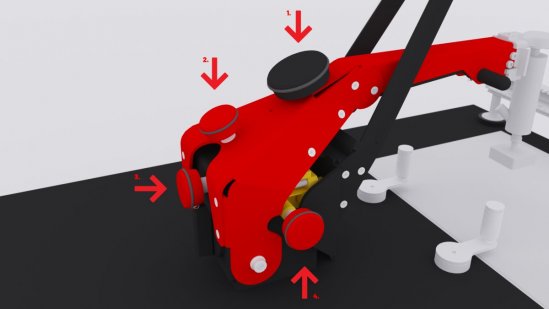

Manual camera-supported adjustment and placement of components via the MCP positioning arm. Precisely aligned to the pad structures of the PCB, it is accomplished in a user-friendly and reliable way.

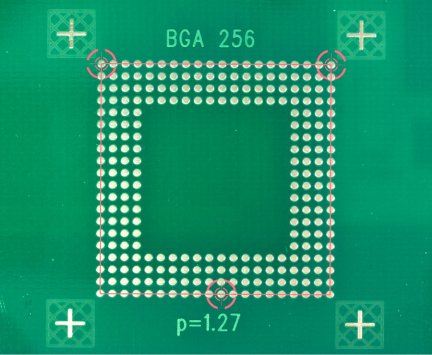

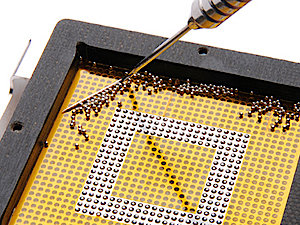

The pre-bumping process can be easily and safely performed with MARTIN's pre-bumping tools. These have been specially developed for use with the MINIOVEN.

DispenseTechnologies

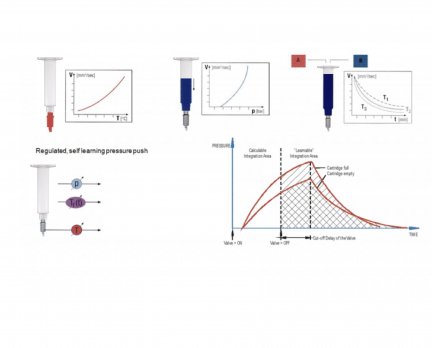

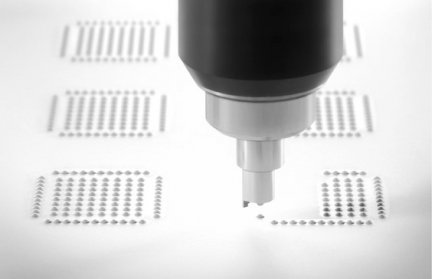

Advanced Time Pressure provides high accuracy, maintenance free and user-friendly dispensing application.

MARTIN dispense systems use stored look-up tables to compensate for viscosity variations caused by temperature changes. This results in constant dispense volumes under production environments.

Should the use of a fixed distance pin not be practical, the height sensor option can provide all the information required for accurate dispensing.

All DOTLINER machines are supplied with a CCD camera. The camera allows, amongst other features, the confirmation of the actual PCB position, compared with the alignment fiducials in the program.

To avoid uncontrolled dripping of material from the dispensing tip the option Retain Vaccum is available. This is especially important when dealing with low viscosities (ie thin liquids).