CLEVER

DISPENSE 06

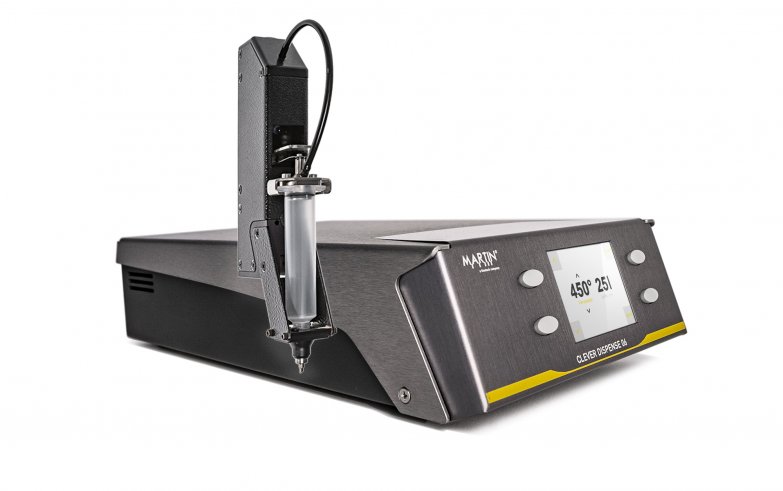

Precise dispensing device with dispensing head, plus optional heating of cartridges and needles for integration into automation technology.

FeaturesAutomated dispensing

CLEVER DISPENSE 06 H DK

The CLEVER DISPENSE 06 H is a professional dispenser for applications that require highest accuracy and a maximum control of material viscosity. These dispensers allow heating of the dispensing nozzle and cartridge. The fully electronic dispensers whose dispensing pressure, temperature and retract vacuum, are program-controlled, use the volumetric time-pressure-technology. This allows reliable dispensing of very small dots and lines of liquid to pasty material either as 1K-type or 2K-type. You can add your own material to the already existing material library to define essential material parameter and limit values. Nozzle heaters are already integrated in the dispensing heads. Furthermore, the cartridge heater can be attached to the CLEVER DISPENSE 06 H which allows the material temperature to be adjusted and controlled. A USB or a TCP/IP interface is provided for communication between dispenser and process computer.

Product variations in the shop

| CD06.1301 | CLEVER DISPENSE 06 H DK 3 dispensing head 3ccm with nozzle heating Article Nr.: CD06.1301 | ||||||

| CD06.1302 | CLEVER DISPENSE 06 H DK 5 dispensing head 5ccm with nozzle heating Article Nr.: CD06.1302 | ||||||

| CD06.1303 | CLEVER DISPENSE 06 H DK 10 dispensing head 10ccm with nozzle heating Article Nr.: CD06.1303 | ||||||

| CD06.1304 | CLEVER DISPENSE 06 H DK 30 dispensing head 30ccm with nozzle heating Article Nr.: CD06.1304 | ||||||

| CD06.1305 | CLEVER DISPENSE 06 H DK 55 dispensing head 55ccm with nozzle heating Article Nr.: CD06.1305 |

Standard equipment

- Control unit CLEVER DISPENSE 06 H

- Dispensing head (size of choice) with integrated nozzle heater

- Connecting cable of dispensing head (standard 2,6m/ max. 3,0m)

- Pneumatic hose (d=6mm, l=5m)

- Power supply 90–230 V AC -> 24V DC

- PC-Software CLEVER DISPENSE Pro

- USB cable

- Short instruction

Materials

- Alcohol

- Silicone

- Thermal conductive adhesives

- Flux

- Solder paste

- Aqueous

- Oil

- Grease

- Underfill

- Adhesive Conductive Paste

Processes

- Glob Top

- Line dispensing

- Dot dispensing

- Microdispensing

- Underfill dispensing

- Adhesive bonding

- Coating

- Preheating of the material

Videos

Application of Delo Photobond DM4083

Industrial research, project no. 19390N „Fadenfrei“

Institute of Joining and Welding,

Technical University Braunschweig

Technical details

| Cartridges to use: | 3, 5, 10, 30, 55 ccm | |

| Viscosity range: | 0.1 - 105 mPas | |

| Nozzle heater: | 90 °C max. | |

| Retract vacuum: | -20 mbar – 0 mbar | |

| Dot dispense settings: | Time range: | 0.001 s -2 s (±0.0005 s) |

| Pressure range: | 0.1 bar – 6 bar | |

| Repeatability: | 1 % (Pressure pulse) | |

| Smallest dispensing volume: | 1.0 nl | |

| Line dispense settings: | Time range: | 0.1 s - 30 s |

| Continuous pressure control | ||

| Repeatability: | 2% (Pressure level) | |

| Communication: | USB 2 (Type B) / SPS / PLC / Network | |

| Dimensions: | 272 x 152 x 60 mm3 | |

| Weight: | 2.5 kg max. |

Options

| Height sensor: | For dispensing head |

| Cartridge heater: | 90°C max. |

Downloads

| Product flyer | 0.8 MB | Download |

Optional extras

| DK06.0001 | Dispensing head 3ccm with nozzle heating Article Nr.: DK06.0001 | ||||||

| DK06.0002 | Dispensing head 5ccm with nozzle heating Article Nr.: DK06.0002 | ||||||

| DK06.0003 | Dispensing head 10ccm with nozzle heating Article Nr.: DK06.0003 | ||||||

| DK06.0004 | Dispensing head 30ccm with nozzle heating Article Nr.: DK06.0004 | ||||||

| DK06.0005 | Dispensing head 55ccm with nozzle heating Article Nr.: DK06.0005 |